Composite Moulding

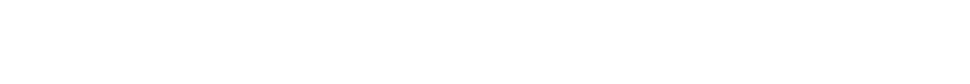

FIBERFLON offers a wide range of high temperature materials used in the Vacuum Bagging Process for advanced composites such as; PTFE coated fiberglass bleeder cloth, release fabrics, PTFE coated & laminated PSA tapes, mold release (MR) and vacuum bagging (VB) PTFE cast films.

Our composite molding process materials are specifically designed to provide non-stick properties and chemical inertness while withstanding highest temperatures in the composite molding temperature range. PTFE bleeder clothes, release fabrics and tapes can be used in temperatures up to 260⁰C while MR Films and VB Films can withstand temperatures up to 316⁰C. These materials are widely preferred for use in the automotive, wind turbine, and aerospace industries.

PREMIUM Series have the highest PTFE-to-substrate ratio that create an extremely smooth, high-gloss surface with excellent abrasion resistance and tensile strength.

PREMIUM Series have the highest PTFE-to-substrate ratio that create an extremely smooth, high-gloss surface with excellent abrasion resistance and tensile strength.

Relevant Brochures

COMPOSITE MOULDING BROCHURES

Your Success is Our Success

We recognize that every customer’s needs are unique as it is with each manufacturing process. The most essential key to our success is collaborative partnership with our customers. We believe working with our customers on a close basis help us understand the specific needs of their manufacturing processes and implement accurate products to maximize productivity and minimize down-time.